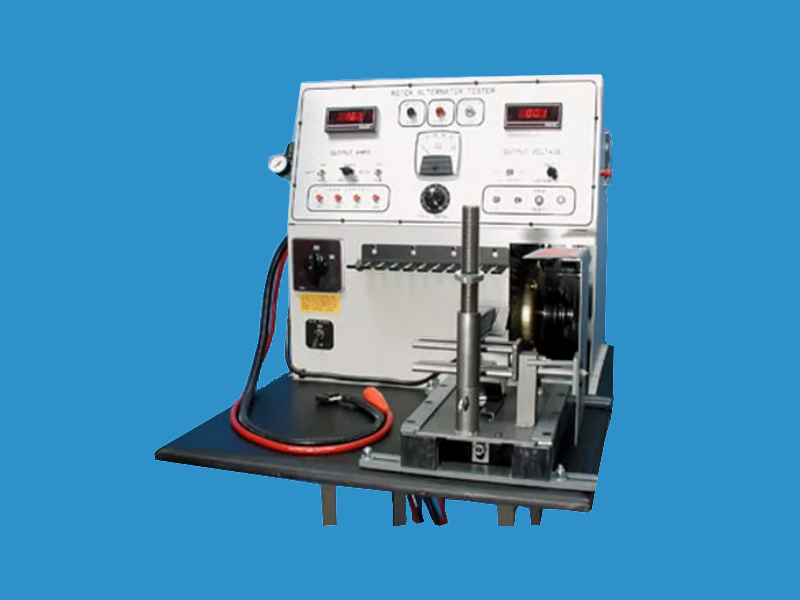

Bench Testing Alternator

Howto bench test an alternator.

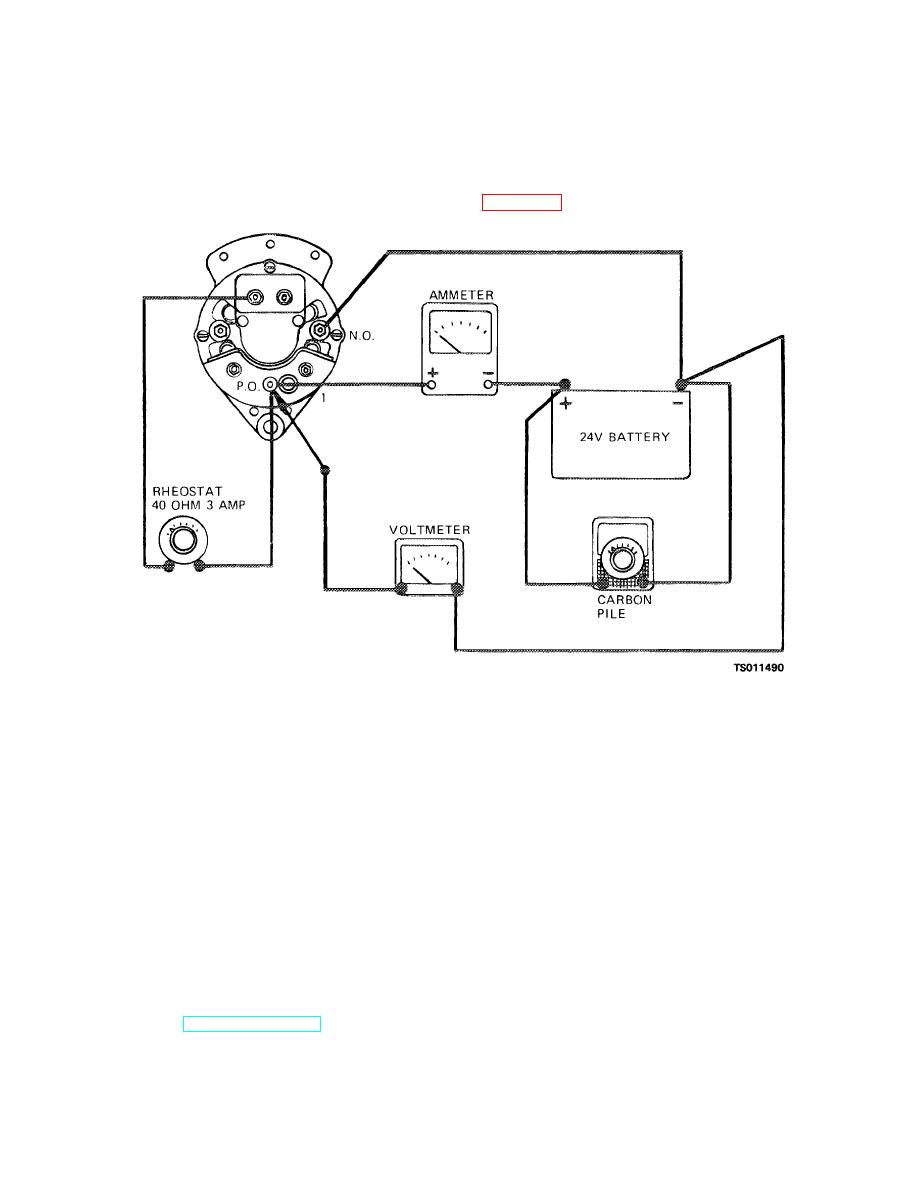

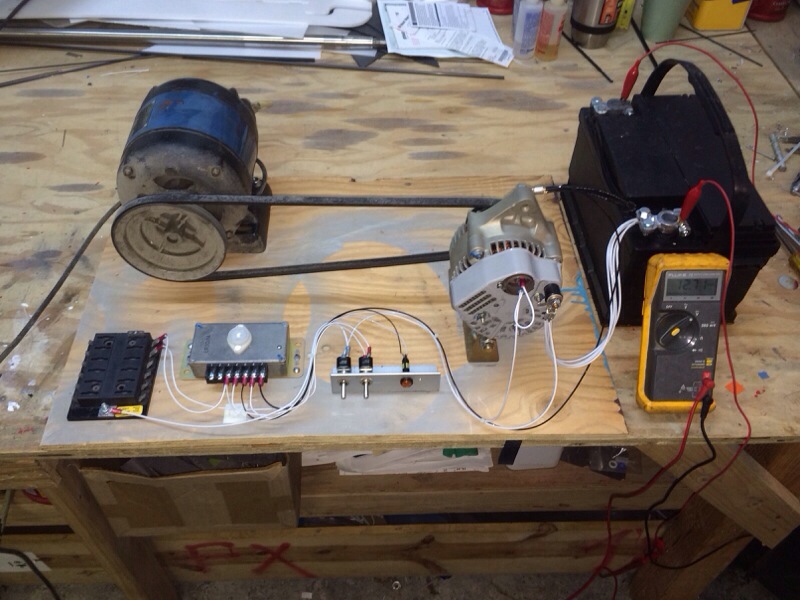

Bench testing alternator. The fast and easiest way to test an alternator with a drill a socket and multimeter this way by spinning will produce electricity and therefore test for its functionality please like a share. If it s below that charge the battery with a battery charger before you conduct the test again. Then start the engine and check for increased voltage readings.

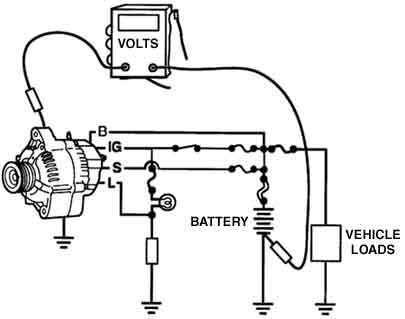

Look at the reading. If the old alternator passes the tests the problem is obviously not the alternator and you ve missed something. If you see higher readings chances are the alternator is good.

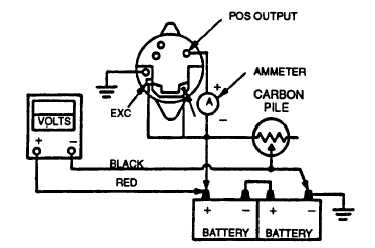

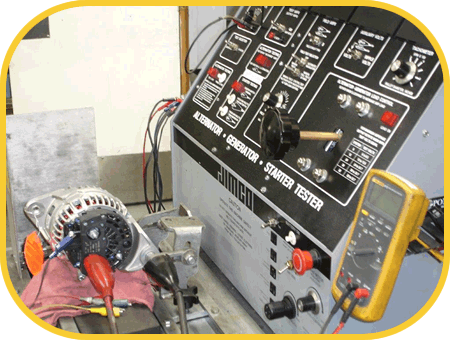

Conduct a voltmeter test. I have my alternator in a vice and i am ready with my volt meter battery and drill but i am not sure how to wire it up. Start date 27 jun 2012.

Bench testing an alternator. It should hover around 12 volts. As rr said it s going to need a voltage applied to it s input so it can actually begin it s function.

Put the black lead on the battery negative terminal. Get a cheap voltmeter. With the engine off battery voltage should be between 12 5 and 12 8 volts.

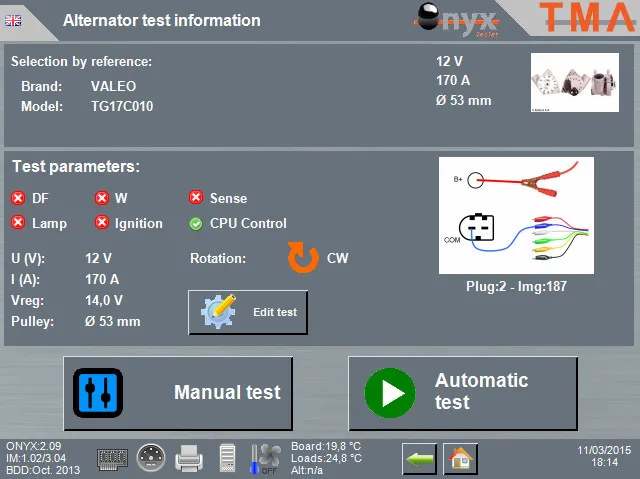

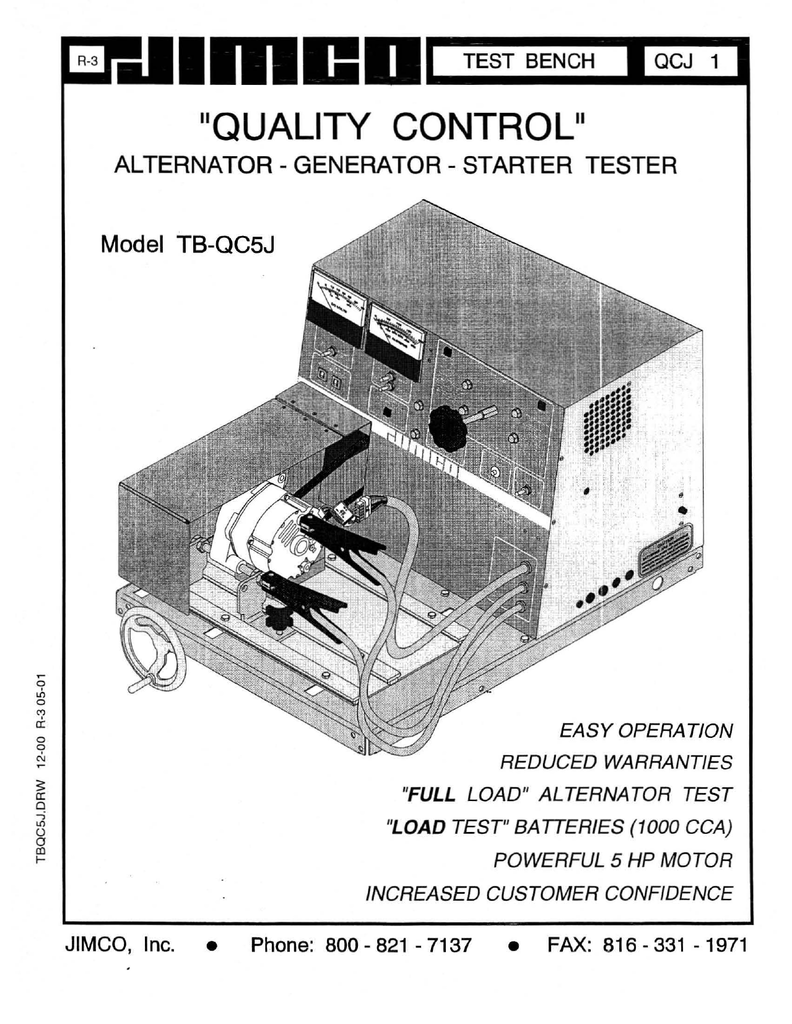

Another approach for reducing comebacks and unnecessary warranty returns is to ask your parts supplier to bench test your customer s old alternator and to bench test the new alternator before you install it. 27 jun 2012 1 gordontytler new member. Joined 26 feb 2012 messages 84.